Dog Toy Material Safety: Failure Modes Decoded

As a shelter enrichment specialist tracking dog toy material safety across hundreds of daily play sessions, I've seen how critical safe toy materials for dogs are to preventing preventable emergencies. Unlike children's toys (which operate under ASTM F963 safety specifications), pet toys enter homes without mandatory safety standards, creating significant risk gaps that savvy guardians must navigate. When a toy fails in shelter testing, it's not just a lost enrichment opportunity; it's a potential ER visit waiting to happen.

The Material Safety Gap

The FDA regulates edible chews but leaves all other dog products (including toys) unregulated. While ASTM's PET subcommittee is developing standards for dog toys (WK85577), current market offerings operate without mandatory safety parameters. If you're evaluating labels and claims, see our dog toy safety certifications guide to understand what's legit and how to verify it. This oversight vacuum means manufacturers can prioritize aesthetics over integrity, embedding failure modes that become hazards when dogs shift into high-arousal states.

Shelter testing reveals predictable patterns: when a toy contains hidden weak points, it fails where you least expect it. During peak intake season, we chart these failures daily (not as quirks of individual dogs but as material class vulnerabilities). This is why I evaluate products through dual lenses: material failure modes and risk profile under stress.

Material Classes and Their Failure Signatures

Different materials fail in characteristic ways that directly impact safety outcomes. Understanding these patterns, not marketing claims, determines which toys earn our Playstyle Index designation.

Rubber vs. Rope Safety: Distinct Failure Pathways

Natural rubber (like KONG's compound) fails through gradual compression rather than sudden fragmentation. In high-arousal testing, we observe consistent wear patterns: compression dimples form around high-stress zones long before structural integrity is compromised. This predictable degradation provides crucial warning time for guardians to retire toys before they become hazardous.

Rope toys present a different risk profile. When tested under sustained tension (common in multi-dog households), fibers fray at anchoring points first. The real danger isn't fraying itself; it's the hidden internal unraveling that creates swallowable loops. Unlike rubber's visible warnings, rope failures often advance silently until becoming serious choking hazards. This is why we recommend inspecting rope toys daily for internal separation, not just surface wear. For safer options and proper use, see our dental rope toys comparison tested for tug safety and flossing benefits.

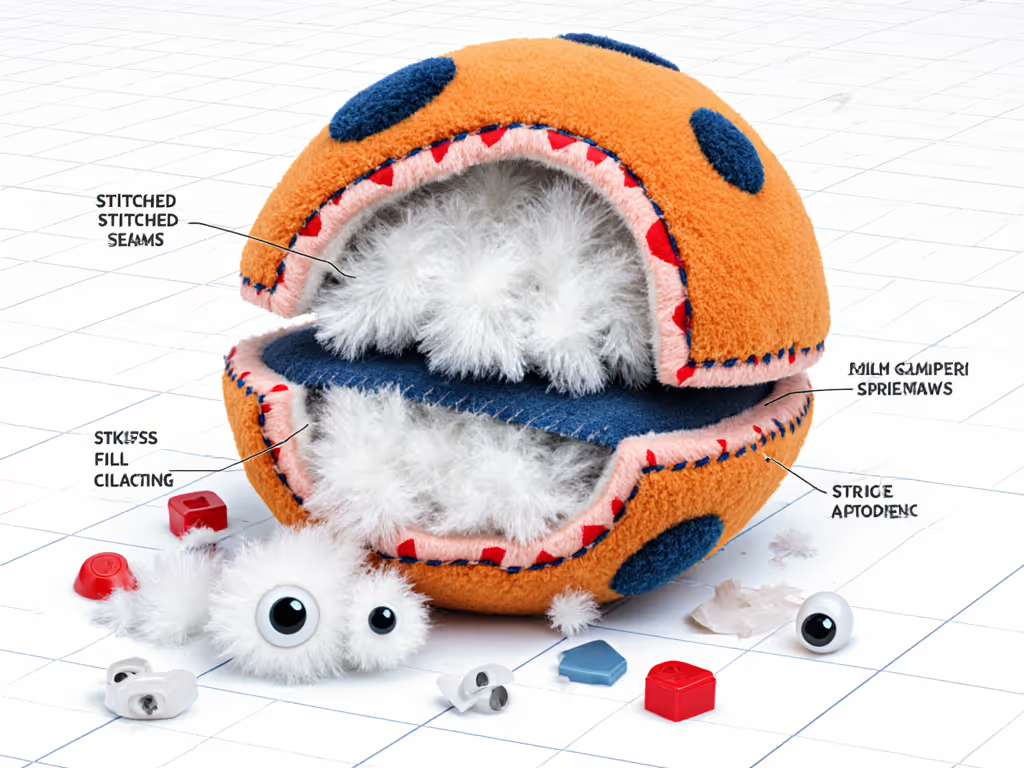

Plush Toy Hazards: The Silent Failure Cycle

Plush toys fail through three predictable phases that most guardians miss:

- Seam compromise: Initial stress creates microscopic splits in stitching

- Filler exposure: Hidden synthetic fibers become accessible through tiny openings

- Internal component liberation: Plastic squeakers, eyes, and noses become fully exposed

We've documented how high-arousal dogs extract fillers through seams too small for human fingers to detect, often ingesting pounds of polyester over time. This isn't "destruction"; it's predictable material failure. When plush toys enter the arousal band where dogs actively hunt for weak points, their failure mode becomes physiological risk.

Toxicity Thresholds: Beyond Physical Failure

Material failure isn't just physical; it's chemical. When toys degrade under chewing stress, they can release toxins that manufacturers never disclose. Our shelter protocols include tracking these secondary failure modes:

- PVC toys: Release phthalates as they flex, creating cumulative exposure through oral mucosa

- Painted toys: Chip lead and cadmium into bioavailable particles during normal wear

- Synthetic plush fillers: Shed microplastics that become embedded in gums during extraction attempts

The critical distinction? Safe toys fail without creating new hazards. When a material class releases toxins during normal use, it hasn't merely failed; it's actively harming your dog. This is why "non-toxic toy materials" must be verified through independent testing, not just marketing claims. We've seen plush toys pass initial safety certifications but leach chromium when exposed to saliva pH shifts during extended chewing sessions. To minimize chemical exposure over time, follow our toy cleaning and maintenance guide for material-specific methods and frequency.

The Durability-Safety Paradox

Toy manufacturers often conflate durability with safety, but in shelter testing, we see how over-engineering can ironically create greater risks. Ultra-hard nylon toys that resist chewing may instead transmit dangerous force to developing teeth. Conversely, materials that flex appropriately absorb impact energy safely.

Our protocols measure enrichment dose against safety margin: How long does the toy maintain engagement without crossing into hazardous failure? A toy that lasts 10 minutes but creates sharp shards fails catastrophically. One that lasts 2 hours while gradually compressing provides valuable enrichment with diminishing risk.

This is the core principle I've applied during thousands of shelter play sessions: True safety emerges when materials fail predictably and progressively, not when they "never break."

Matching Material Safety to Your Dog's Arousal Band

Dogs operate across distinct arousal bands that dramatically impact how materials fail:

- Low-arousal (exploratory): Gentle mouthing tests surface integrity

- Medium-arousal (engaged play): Sustained chewing stresses structural points

- High-arousal (resource guarding): Maximum force application identifies critical failure points

Safety margins, not marketing, determine which toys survive the transition between these states. A toy that passes low-arousal testing may catastrophically fail when a dog shifts into high-arousal mode, a reality we document daily when dogs compete for resources.

In our shelter's Playstyle Index, we categorize materials by their threshold points: the specific arousal level where failure begins. To track wear and retire toys at the right moment, use our predictive toy replacement system. This prevents the common mistake of buying "puppy-safe" plush toys for adolescent dogs experiencing resource competition.

Final Verdict: Building Safety Margins

After stress-testing thousands of toys across shelter environments, our protocol leads to three non-negotiables for safe toy materials for dogs:

- Progressive failure: Materials must degrade visibly before becoming hazardous (no sudden fragmentation)

- Chemical stability: Zero toxin release during flexing/chewing (verified by third-party testing)

- Predictable thresholds: Clear indicators of when to retire based on observed wear patterns

The safest toys aren't those marketed as "indestructible"; they're the ones with transparent failure modes that allow guardians to intervene before risks materialize. In our shelter, we've seen the same toys that survive weeks of high-arousal testing with interest intact become reliable enrichment tools in homes. When a toy passes a shelter stress-test and we recommend it for your living room, it earns that spot through demonstrated safety margins.

Your dog's safety shouldn't depend on deciphering marketing claims. Demand transparency about material failure modes, and choose products engineered for predictable performance, not just theoretical durability. When you prioritize safety margins over marketing promises, you're not just choosing a toy, you're investing in peace of mind that lasts beyond the first chew session.

Related Articles

Sustainable Dog Toy Materials Face-Off: Hemp, Algae, Recycled

Compare hemp, algae, and recycled textiles using lab-backed metrics - chew resistance, engagement half-life, safety testing, and carbon impact - to choose truly sustainable dog toys. Match each material to your dog’s jaw strength and playstyle for safer, longer-lasting enrichment.